|

| September 18, 2018 | Volume 14 Issue 35 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

NASA targets three ideas to pursue to help transform aviation

The Convergent Aeronautics Solutions project funds NASA researchers to explore the feasibility of big ideas. [Credits: NASA/Andrew Carlsen]

By Jim Banke, NASA's Aeronautics Research Mission Directorate

Like a collection of savvy entrepreneurs gathered to hear new business proposals in a "shark tank," NASA's aeronautical innovators always are looking for the "next best thing."

In the fourth year of NASA's Convergent Aeronautics Solutions (CAS) project, which is designed to identify and nurture that next best thing, three new ideas will be given time and resources to determine if they are technically feasible and perhaps worthy of additional pursuit within NASA or industry.

"This year's selections represent a broad range of research topics, yet each could significantly contribute to building future aircraft that are more energy efficient, produce fewer emissions, and are quieter," said John Cavolowsky, NASA's director of the Transformative Aeronautics Concepts program, which manages CAS.

The selected projects for the 2019 fiscal year that begins Oct. 1 involve a new assembly technique with composites, finding ways to reduce and shed heat generated by an electric motor, and exploring use of a water-based solution for generating electricity to replace lithium-based batteries.

Sticking together

Future aircraft designs may look much differently than today's familiar configuration. The wings and tail, for example, might be seamlessly blended with the main hull in one continuous line.

Future aircraft may feature unusual looks made possible through the use of composite structures. Bonding composite parts together in a more efficient manner is one of the ideas selected for study by the Convergent Aeronautics Solutions project. [Credits: NASA]

These exotic designs -- which could reduce fuel use, emissions, and noise -- will be easier to build using composite materials, which theoretically can be manufactured in any shape.

But joining larger aircraft parts made of composite material currently requires they be bolted or riveted together as though they were made of metal. That adds weight, and drilling thousands of holes to install those bolts is time consuming and costly.

It would be much better to assemble the composite parts by bonding them together, which in the long run would make the aircraft safer and less expensive to operate and maintain.

"While adhesive bonding is quite reliable, there can be scenarios where they may not meet the stringent requirements for certification from the FAA," said NASA's Frank Palmieri, one of the principal investigators of the Adhesive Free Bonding of Composites project chosen as part of this year's CAS selections.

In a factory setting, when an adhesive is added to a solid surface, there always is some concern of contamination just before the parts are bonded no matter how much care is taken, so there always is a possibility that a weak bond is formed.

"And you can't inspect it. There's no measuring method that exists that can say with certainty how strong your joint is unless you break it," Palmieri said.

Solving that inspection dilemma by introducing a new manufacturing technique to safely and reliably bond composite structures together while minimizing -- or eliminating -- the need for intrusive bolts or rivets is what this project is all about.

That proposed technique involves how and when two composite structures and a layer of composite laminate material in between them are cured such that the result is one complete, fully bonded, seamless part with no concerns the joint isn't sound.

"This isn't about making a stronger adhesive or laminate. We're trying to make a more reliable and predictable interface between the parts," Palmieri said.

Beating the heat

Hybrid-electric and all-electric airplanes under study by NASA, such as the general aviation-sized X-57 Maxwell, will rely on motors that generate heat -- heat that if not generated would make the motors operate more efficiently.

Hybrid-electric and all-electric airplanes under study by NASA, such as the X-57 Maxwell, could operate more efficiently if its motors generated less heat and the overall system was better at shedding the heat. A possible solution to that goal will be studied during the next two years as part of the Convergent Aeronautics Solutions project. [Credits: NASA Langley/Advanced Concepts Lab, AMA, Inc.]

As the airplanes get bigger -- such as NASA's theoretical, partial turbo electric single-aisle airliner, STARC-ABL -- the electric motors need megawatts of energy to operate, and the resulting heat load will be substantially greater.

Today, the traditional way for an aircraft to keep its power system cool is to collect the heat and get rid of it at a single heat exchanger, said NASA's Ralph Jansen, a principal investigator for the High-Efficiency Electrified Aircraft Thermal Research (HEATheR) project selected this year by CAS.

Such a system adds weight and drag to an airplane, which requires the propulsion system to work harder, which in turn drives up operating and maintenance costs. If successful, HEATheR would provide an option to reduce those burdens.

"What we want to do is minimize the heat from the whole power system by finding different ways of designing the power-related components themselves and coming up with different ways of putting those components together inside the aircraft," Jansen said.

To reach this goal, the main idea is to reduce the number of parts needed in the motor and at that same time make those parts smaller -- both of which would result in less heat generated.

New ideas for shedding that reduced heat will be considered as well, including using the outside skin of the aircraft itself as a sort of radiator. But don't worry, those in a window seat wouldn't feel any warmer, Jansen said.

Ultimately, HEATheR researcher's biggest challenge in making all of this work is to find a new design for the entire power system, from electric motors to power distribution, that is better than the current state-of-the-art system.

"Electric motors have been around for a century and power electronics for some 35 years; they are well understood. So, the things we're trying to do to squeeze out additional improvements in this area are pretty difficult," Jansen said.

Power in water

As the desire increases to rely more heavily on aircraft propelled in some fashion using electricity, the demand for lithium-based batteries is growing at a rate that may not be possible to meet some day given the available supply of the element on Earth.

At the same time, lithium batteries, in combination with the cables and electronics associated with current power distribution systems proposed for use in future electric-powered aircraft, have proven to have some safety and operational risks associated with them.

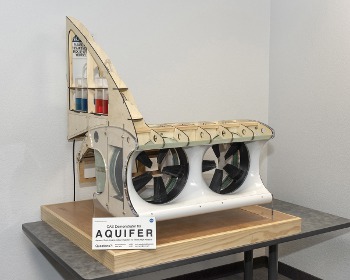

Selected for study by the Convergent Aeronautics Solutions project, AQUIFER researchers will look into using an iron-infused solution of water in a flow battery that powers an electric rim motor. The hope is this system will prove to be feasible for use as a more efficient way to power electric aircraft and reduce reliance on lithium batteries. [Credits: NASA/Ken Ulbrich]

This includes concerns about battery fires, the mass and volume needed for energy storage, managing heat loads, electronic noise from long power cables interfering with onboard systems, and logistics related to re-charging the batteries between flights -- among others.

The answer to many of these issues might be found by using a specific type of electric motor that is powered by using a water-based, iron-infused solution instead of batteries.

Combining those two technologies together for the first time in an aviation setting is the central idea behind "Aqueous, QUick-charging battery Integration For Electric flight Research," or AQUIFER.

The electric motor is called a rim motor because instead of turning a central shaft, the energy is applied to the outer perimeter of a spinning propeller or fan. This requires less torque, reduces drag, and can even lessen the noise coming from the powerplant.

"Think of a person in a wheelchair who moves around by applying force to the outside rim of the wheels. It's a lot easier to move the wheel that way than if the person had to twist a shaft at the wheel's hub," said NASA's Kurt Papathakis, an AQUIFER principal investigator.

Use of the rim motor becomes even more ideal when combined with the proposed power source, which is known as a flow battery.

In the case of AQUIFER, the flow battery includes two supplies of a water-based solution, each stored in their own tank. In both tanks the water is infused with a high concentration of very tiny iron particles and other proprietary material.

In one of the tanks, the iron particles have a positive charge, and in the other a negative charge. Both fluids are pumped past a porous membrane, which allows the two fluids to interact and generate a current of electricity.

The bigger the membrane and/or the more volume of fluid that is pumped past the membrane, the more power that is generated. The fluids are then returned to their tanks and are constantly recirculated until the end of the flight, which would happen long before the fluids would lose their charge.

Conceptually, the airplane's tanks would then be drained, filled with fresh solution, and the aircraft would be ready for another flight in a vastly shorter amount of time than it would take to re-charge any batteries.

"Each of these concepts -- the rim motor and flow battery -- have their own merit, but together they allow us to really showcase the benefits this system could have for an electric-powered vehicle of almost any size," Papathakis said.

But no one has ever tried to put these technologies together and do it in the air, and Papathakis and his team are fully aware they may learn this might not be feasible.

"Who knows? All of us appreciate we're selling a lot here, but everything we've seen so far has looked good and remained on schedule," he said.

Tough choices

The three studies were selected by a team of NASA aeronautics managers, led by Cavolowsky, who made their decisions after two days of hearing from principal investigators representing more than a dozen proposals.

To be considered, teams had to form on their own, represent multidisciplinary talents, and have members from more than one of NASA's field centers in Virginia, California, and Ohio, where aeronautics research is a major focus.

The prospect of transitioning these truly unique, out-of-the-box-thinking ideas from feasibility studies to more advanced research opportunities earned increased emphasis in this year's selections.

"It is important to have a plan in place so that if an idea proves feasible and shows promise, our researchers have a good notion where their results can be helpful in other NASA programs or within industry," Cavolowsky said.

The three selected proposals this year join three that were selected in 2017, five that were selected in 2016, and six that were selected in 2015.

SIDEBAR: What else is NASA working on? Electric airplanes (batteries included)

By Bob Silberg, NASA's Jet Propulsion Laboratory

If there were no need for massive batteries, electric propulsion could dramatically reduce aviation's contribution to climate change from carbon dioxide emissions. But what if the plane, itself, were the battery?

Suppose an aircraft's skin or floor, for example, could serve double duty by storing and dispensing electrical energy without adding substantially to the weight of the materials currently used. That could bring us a lot closer to practical electric flight on a meaningful scale.

What if the plane itself -- its skin or floor -- were the battery? The goal of eliminating -- or at least reducing -- the need for separate batteries drives a team of some 35 scientists and engineers working on another NASA project.

What's wrong with batteries? For one thing, they're very heavy. Today's best batteries would increase a small plane's weight by about a third. A large plane's weight would go up by a similar fraction even with highly improved batteries, four times as efficient as today's best. Lifting all that battery weight eats up a lot of the energy that would be better put toward moving people and cargo.

Batteries take up a lot of space, too. And accommodating them, whether inside or outside the plane, increases drag -- air resistance that wastes still more energy.

The goal of eliminating -- or at least reducing -- the need for separate batteries drives a team of some 35 scientists and engineers, working at four NASA centers and led by Patricia Loyselle of NASA's Glenn Research Center in Cleveland, OH. Their project, called M-SHELLS (for Multifunctional Structures for High-Energy Lightweight Load-bearing Storage), falls under NASA's Transformative Aeronautics Concepts Program. TACP supports efforts that have a high risk of failure because of their ultra-challenging nature, but which will pay off big if they succeed. And in this case, the benefits could potentially go far beyond aeronautics.

"We would love to see our developments incorporated in things like cars as well as aircraft," Loyselle said. "You could use it for some of the structures that go up into space. It could be for buildings. It could be pretty much anywhere you need energy and a structure at the same time."

For the M-SHELLS project to succeed, it needs to create material that is as strong as today's aircraft-construction materials, can store large amounts of energy and both charge and dispense that energy rapidly. "You don't want to sit around for four hours waiting for the battery to recharge," Loyselle said. "And if somebody wants to change altitude, we want to be able to deliver the power quickly."

The team is trying to merge two kinds of energy technology. "We are developing what's called a hybrid supercapacitor that's got the qualities of a battery as well as the qualities of a supercapacitor," Loyselle said, noting that batteries are able to store a lot of energy whereas supercapacitors are speed demons for charging and discharging.

Some newly available materials may provide the means. "Some of these new nano materials are very, very strong," Loyselle said. "And if you have that real small particle size, reactions happen much faster."

Published September 2018

Rate this article

View our terms of use and privacy policy